Digsau, an architecture firm out of Philly, worked with Oldcastle Precast to come up with this $99K house entry, which uses some concrete technology more commonly encountered in Houston area civil structures:

Digsau, an architecture firm out of Philly, worked with Oldcastle Precast to come up with this $99K house entry, which uses some concrete technology more commonly encountered in Houston area civil structures:

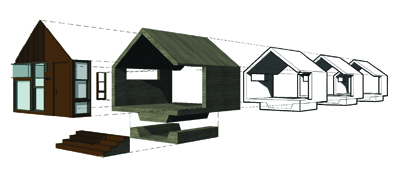

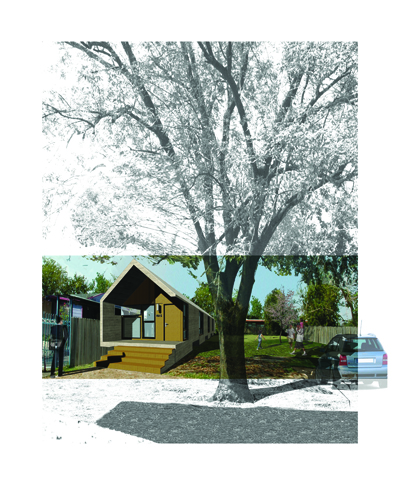

A concrete module serves as the building block for the system, and its combination with other modules allows the structure to respond to specificities of climate, site, and individual preference. The system thus proves highly adaptable as an infill structure on vacant properties in an urban context and allowing for a diversity of exterior space in new developments.

***

The mass and solidity of the concrete shell is balanced by the warmth and refinement of the natural wood infill panels, doors and windows. Infill panels with operable window units promote views and natural ventilation. The relationship of these elements both defines and obscures the perception of interior and exterior space.

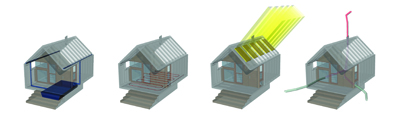

Sustainable features are embedded within the highly efficient fabrication process which results in an efficient, low waste construction process that would fabricate re-usable, no-maintenance structural units. The embodied energy contained in concrete would be offset by reduced construction waste, elimination of future maintenance, and the high performance environmental qualities of the exoskeleton. The monolithic shells provide a tight, durable enclosure that results in controlled ventilation and reduced mechanical requirements.

A radiant floor heating system and mechanically assisted natural ventilation systems provide environmental control. The embodied energy contained in concrete is greatly reduced by using fiber-reinforced material. In addition, reduced construction waste, elimination of future maintenance, and the high performance environmental qualities of the exoskeleton are advantages of this system.

Swamplot is featuring home designs by participants in the 99K House Competition sponsored earlier this year by the Rice Design Alliance and the Houston Chapter of the AIA. You can see all the competition entries Swamplot has featured so far on this page.

- Digsau (click on “work,” then “Shell House” to see more images)

- Program/Budget [the 99K House Competition]

- $99K House Competition: The Series [Swamplot]

Images: DIGSAU, in collaboration with Oldcastle Precast Inc. Design team: Jules Dingle AIA, Jeff Goldstein AIA, Mark Sanderson AIA, Jamie Unkefer AIA

While I like the concept, the concrete used in the box culvert structure and the homes will be nowhere near the same in strength. If they were, you can kiss that $99k good-bye.

The box culvert structure in the picture appears to be a 10’x10′ structure. Segment lengths are 8′. At this size, only one segment per 18-wheeler can be transported. The box culvert system alone in the picture above costs more than $200k.

It’s great at illustrating the ease of construction, but not cost.

Do I think the house concept doesn’t work? Hell no. It is an awesome concept and could easily meet the $99k price point. It goes back to the strength I mentioned before. The concrete used in the proposed application (fiber reinforced) is commonly used all over Houston right now. All of the strip centers, distribution centers, suburban office buildings, and hotel/motels have been using this concrete for years to hang on exterior walls. It’s lightweight high strength concrete. All it’ll take is a factory to manufacture it into the shapes for housing and not panels for steel building cladding.