LOOKING FOR THE METAL STUDS IN HOUSTON  “I got nothing against wood,” writes a reader who says he worked in his uncle’s construction business for 12 summers while he was in school. “I really like the smell of fresh cut wood.” Still, he’s hoping Swamplot readers will be able to refer him to both architects and residential builders who are familiar with metal-frame construction — to help him build a new home for himself in the Memorial Villages area. He says he’s convinced metal-frame construction will last longer in Houston because of its inhospitality to termite dining and perhaps a lower risk of going up in flames. [Swamplot inbox] Photo: Super Stud

“I got nothing against wood,” writes a reader who says he worked in his uncle’s construction business for 12 summers while he was in school. “I really like the smell of fresh cut wood.” Still, he’s hoping Swamplot readers will be able to refer him to both architects and residential builders who are familiar with metal-frame construction — to help him build a new home for himself in the Memorial Villages area. He says he’s convinced metal-frame construction will last longer in Houston because of its inhospitality to termite dining and perhaps a lower risk of going up in flames. [Swamplot inbox] Photo: Super Stud

Construction Materials

GETTING TO THE BOTTOM OF THE WILLIAMS TOWER  The $412 million sale last week of the Williams Tower seems to have provoked some curiosity in the Houston Chronicle’s Katherine Feser: Pursuing a lead from a retired employee that, were it not for those pesky FAA regulations, the record-breaking 64-story skyscraper would have been even taller, Feser goes into the paper’s archives and finds evidence that the tower’s slab was something to behold, too: “The foundation pour . . . started at midnight Friday and was completed early Saturday night. The contractor, J.A. Jones Co., said it was believed to be the largest continuous pour ever made in Houston — more than 10,000 cubic yards of concrete. There have been larger pours but they have been completed in several stages. The area of the poured mat is 200 feet by 200 feet, almost an acre.” [Prime Property; previously on Swamplot] Photo: Russell Hancock

The $412 million sale last week of the Williams Tower seems to have provoked some curiosity in the Houston Chronicle’s Katherine Feser: Pursuing a lead from a retired employee that, were it not for those pesky FAA regulations, the record-breaking 64-story skyscraper would have been even taller, Feser goes into the paper’s archives and finds evidence that the tower’s slab was something to behold, too: “The foundation pour . . . started at midnight Friday and was completed early Saturday night. The contractor, J.A. Jones Co., said it was believed to be the largest continuous pour ever made in Houston — more than 10,000 cubic yards of concrete. There have been larger pours but they have been completed in several stages. The area of the poured mat is 200 feet by 200 feet, almost an acre.” [Prime Property; previously on Swamplot] Photo: Russell Hancock

Ah, Friday: Why not take a stroll down Binz St. in the Museum District and have a look at what’s going on? Let’s head east from here: the corner of La Branch and Binz, near the Children’s Museum.

Our guide, Swamplot reader David Hollas, provides the photos and the observations:

Thieves made off with copper wiring from UH’s University Center late Saturday night, a UH public safety department bulletin reports: A contractor noticed early Sunday morning that the wiring had gone missing; a reader tells Swamplot that this knocked out the building’s power and is delaying renovations. The Barnes & Noble and Cougar Byte stores inside the UC have been scrambling to set up temporary locations elsewhere on campus.

COMMENT OF THE DAY RUNNER-UP: STICKING UP FOR STUCCO “What’s with all of this unfounded hate for stucco? It’s actually a very good construction material, well suited for wet climates (if installed properly). One can have just as much water penetration and mold on a brick facade if flashings are not installed properly or weep holes are clogged. And unlike brick, stucco actually ‘ties’ the structure together by making the frame more rigid, whereas brick just sits there almost unconnected from the structure.” [commonsense, commenting on A Preview of a $110K Modest Mod]

Whoever owns this warehouse in the East End — he wants to remain anonymous — has donated it for the time being to Historic Houston to house its collection of materials rescued from historic Houston buildings before demolitions turned everything into splinters and twisted metal.

The warehouse is located between Eastwood and Milby at 4300 Harrisburg, right next to the monolithic Maximus Coffee Group plant. This Sunday the mural-covered doors will be rolled up for a few hours while the nonprofit rolls out an inventory including windows, light fixtures, flooring, and siding. Founder and executive director Lynn Edmundson tells Swamplot that the group has been looking for a permanent home since early December; it had leased a warehouse and yard at 1307 W. Clay until closing in June 2011.

- Salvage Warehouse Reopens (PDF) [Historic Houston]

- Previously on Swamplot: Fundraising to Reopen Historic Houston’s Salvage Warehouse, Historic Houston Salvage Warehouse Going Out of Business, Selling Everything at Auction, Can Historic Houston’s Salvage Warehouse Be Salvaged?

Photo: Historic Houston

A FAKE STREET FOR REAL ESTATE SHOPPERS IN SPRING  Opening in February, reports CultureMap, is a 10,000-sq.-ft. real estate “park” where a dozen lavishly turned-out showcase homes, ranging in styles from “The Midtown” to “The Calais” to “The Ashby Manor,” are presented for your perusal on a private cul-de-sac near I-45. Think of the immersive, don’t-mind-if-I-do shopping at IKEA blown up to the scale of Disney World — except at MainStreet America there will be fireworks and Christmases and tailgating parties and almost everything will be for sale: “Do you like the paint color, the metallic faux technique on the ceiling or the graphic wallpaper accent in the bedroom? The details are available and so are the prices. In fact, you can make the purchase on site. If that couch, occasional table or rug is what you are looking for, swap that credit card and have them delivered. Floral arrangements? Yes, those are for sale as well. Mirrors? Check. Artwork? In stock. Window treatments? You bet.” Admission for adults is only $10; children aged 5-17 can get in for half that. [CultureMap] Photo: MainStreet America

Opening in February, reports CultureMap, is a 10,000-sq.-ft. real estate “park” where a dozen lavishly turned-out showcase homes, ranging in styles from “The Midtown” to “The Calais” to “The Ashby Manor,” are presented for your perusal on a private cul-de-sac near I-45. Think of the immersive, don’t-mind-if-I-do shopping at IKEA blown up to the scale of Disney World — except at MainStreet America there will be fireworks and Christmases and tailgating parties and almost everything will be for sale: “Do you like the paint color, the metallic faux technique on the ceiling or the graphic wallpaper accent in the bedroom? The details are available and so are the prices. In fact, you can make the purchase on site. If that couch, occasional table or rug is what you are looking for, swap that credit card and have them delivered. Floral arrangements? Yes, those are for sale as well. Mirrors? Check. Artwork? In stock. Window treatments? You bet.” Admission for adults is only $10; children aged 5-17 can get in for half that. [CultureMap] Photo: MainStreet America

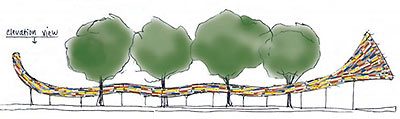

We shall see whether art can have a trickle-down effect: Glasstire reports that Patrick Renner will be taking a few loads of reclaimed wood and building this 185-foot “Funnel Tunnel” among the trees on the esplanade near Inversion and the Art League Houston at 1953 Montrose; the Houston-based sculptor will be piecing it together starting February 1.

- Renner Funnel Tunnel Coming [Glasstire]

Drawing: Glasstire

COMMENT OF THE DAY: WHAT IT TAKES TO BUILD AT THE UPPER END “You are right that you can build a very nice house for $150/sq. ft., but when you are in this stratospheric range, $150 is your starting point and you jump off from there. . . . Your roof will be slate and not composition. Goodness knows how much that costs, and how it impacts your structural engineering. Your floors will be stone and/or wide plank salvaged wood and not 2 1/2″ plain sawn oak. Your facade will be brick, not hardi plank, and bricks will cost $2-$3 each and not 50 cents. And on an 8,000 sq. ft. structure you may get 50,000, 100,000 bricks. Then you pay the mason. Your trim and doors will be custom manufactured and not stock. Your window package will be custom manufactured and not stock. Saw one house where custom fabricated metal windows cost $250,000. For the windows. Your light cans will cost 10x the cost of the cans you get in a builder spec house. You will have paid a lighting designer a fortune to tell you how to position those lights. Your HVAC, security, A/V systems will be state of the art, each of which will run tens and tens of thousands, if not more. You will insulate your house to an extreme level. And so on and so on. It all adds up . . . But yes, you can build a nice house for $150/sq. ft., but if you are building on a 50,000 sq. ft. lot on the corner of Kirby and Inwood, you just won’t.” [KG, commenting on Houston Home Listing Photo of the Day: Out of the Closet]

For the home she’s building for her family on Banks St., on the former site of a carefully disassembled Ranch house in Ranch Estates, architect Karen Lantz tried to make sure every product was made in the United States. But the breaking point came with cabinet hardware, Mimi Swartz writes: “‘This one?’ Lantz said, picking up the pull on the left and turning it over for my inspection. ‘From Italy. Nine dollars.’ She picked up the one on her right. ‘This one?’ She paused. ‘China. Four dollars.’ The U.S.-made pull that was closest to what she wanted cost $72. She called company after company trying to do better. When she asked why the American pulls cost so much more than those made overseas, the answers ranged from ‘We make them here’ to ‘It’s a classic.’”

COMMENT OF THE DAY: WHY WE REALLY NEED THE EARLY MORNING CONCRETE CURE “It’s partly due to traffic, but the main reason you pour concrete in the extreme early hours is due to temperature. Concrete is actually a substance undergoing a chemical reaction and continues to get warmer. In the south, it’s not uncommon to pour concrete in the early morning hours before it gets too hot. If the concrete gets too warm it becomes brittle really fast. There are ways of dealing with heat such as adding ice to the mix, but it is not the preferred way to go. This is also the reason why in west Texas you don’t see to many concrete roads. It’s really hard to maintain the temperature during a large placement. So yes, there is some concern with traffic, but it has to do more with heat. Now, some of you may say that the slab of your house was placed in the heat of the day. Yes, but the strength lost in the heat for your house is not enough to effect the overall structure. Bridges, highways, highrises, and large placements where high loads are experienced can get susceptible to the heat and weaken the overall structure. . . .” [kjb434, commenting on About Those “Early Morning†Concrete Pours]

COMMENT OF THE DAY: YOU PAY, WE SALVAGE “. . . Under the new business model, which is consistent with national models used by various non-profits involved in deconstruction and restores involved in reselling reclaimed materials, the donor of the house will now pay to have the materials reclaimed because they are the ones benefitting from the charitable contribution for the gift of the materials. As an example . . . a property owner could simply demolish a house . . . send everything to the landfill and they will have a cost associated with that for about $8,000.00 with no tax benefit. OR . . . the donor can donate the house to Historic Houston, pay for us to deconstruct/salvage the house, which may cost an additional 3,500-5,000.00, so a total cost of let’s say 13,000.00 to demolish the house. In every instance I have ever dealt with, the charitable contribution for the gift of the materials FAR EXCEEDS the total cost of the demolition and salvage sometimes multiple times over. . . . If doing deconstruction and reclaiming building materials was such a HUGE profit center and money making proposition . . . there would be all kinds of competition out there in this growing market . . . but in fact there’s not . . . because it’s really hard work getting the material out, and storing the material until someone (hopefully) buys it is really expensive and the profit margin is incredibly low . . . thrift store value. . . .” [Lynn Edmundson, commenting on Fundraising To Reopen Historic Houston’s Salvage Warehouse]

FUNDRAISING TO REOPEN HISTORIC HOUSTON’S SALVAGE WAREHOUSE  Historic Houston is kicking off a fundraising campaign with an event 2 Sundays from now in a Woodland Heights home in the process of being restored. According to executive director Lynn Edmundson, the afternoon fundraiser will be “the first of many” targeting the $350K needed before the organization can lease a location for a new salvage warehouse. Historic Houston’s salvage warehouse on Clay St. was shut down last year. Edmundson reports the business model for the salvage program has changed in the meantime: Salvaging salable parts from older homes is now “a fee-based service that is paid by the person that donates the house to Historic Houston,” she tells Swamplot. [Historic Houston; previously on Swamplot] Photo: Historic Houston

Historic Houston is kicking off a fundraising campaign with an event 2 Sundays from now in a Woodland Heights home in the process of being restored. According to executive director Lynn Edmundson, the afternoon fundraiser will be “the first of many” targeting the $350K needed before the organization can lease a location for a new salvage warehouse. Historic Houston’s salvage warehouse on Clay St. was shut down last year. Edmundson reports the business model for the salvage program has changed in the meantime: Salvaging salable parts from older homes is now “a fee-based service that is paid by the person that donates the house to Historic Houston,” she tells Swamplot. [Historic Houston; previously on Swamplot] Photo: Historic Houston

COMMENT OF THE DAY: DEMOLITION IS IN THE EYE OF THE BEHOLDER “. . . I see lots to be salvaged and given to Habitat for Humanity. All that wood flooring, everything in the kitchen, especially the stainless countertop and appliances, french doors, louvered closet doors, balcony railings inside and out, granite bar top and light fixture, bathroom cabinets and granite countertop, tub. Not sure if the tile flooring can be taken up, and the plate glass windows would be tough to pull without breaking. I would love to plan and build a house around items from Habitat. I have seen some very unique things there. For now, I just have a greenhouse with a door, leaded glass sidelight, and jalousie windows from Habitat. And some really neat ceramic tiles that I plan on putting on the potting bench. I’m going to go back and get reclaimed brick for the patio.” [Lynn, commenting on Daily Demolition Report: Passing the Red Baton]

The epic Software Group is now passing around pix of the “creative co-op” building the company painstakingly constructed next to its Woodlands headquarters over the last 18 months — out of 11 recycled shipping containers and a slew of other recycled materials. The 8-ft. x 40-ft. x 9-1/2-ft. containers, explains company president Vic Cherubini, are each 8-9 years old and still rated “sea worthy.” Around that core, the animation, multimedia and web development company production company built an almost-5,000-sq.-ft. building with a large video production studio inside. The assembly sits 50 ft. away from Epic’s own facility at 701 Sawdust Rd., and is now occupied by several creative companies in the area — who pre-leased it before completion.

How’d they put the thing together?